High Pressure is a further

development of vacuum forming.

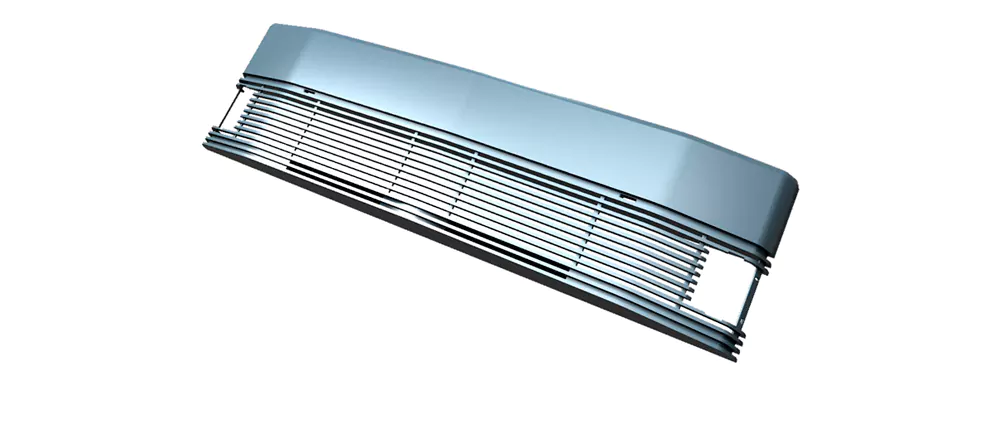

The high quality results match injection-moulded details. The method yields a fantastic level of detail and a very high finish, lower tooling costs and shorter lead-times.

The process has a limited environmental footprint as the material does not contain any solvents; neither does it cause any harmful emissions.

Typical applications

Medical equipment, lighting, doors, shutters, front panels, components for the aerospace, boats, cars and trains.

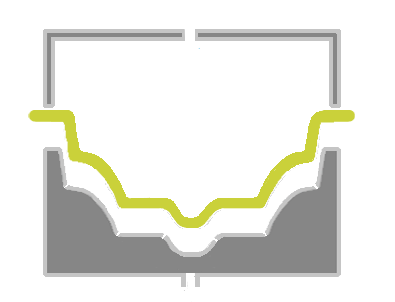

1. Vacuum forming tool

The tool is placed in the High Pressure machine. The sheet is inserted.

2. Heating

The sheet to be formed is heated from above and below to between +170-210°C.

3. Compressed air

Using compressed air, the warm and soft sheet is pushed down into the tool. Up to a pressure of 5 bar. Around five times the pressure used in the injection-moulding process.

4. Cooling

Once the sheet has been moulded it is cooled and is then ready for after-machining.

Sounds interesting? Do you want to know more?

Our manufacturing processes makes opportunities to countless combinations of possibilities for your product.